The ERG Process

Our full-service, patented technology converts organic waste streams into Exceptional Quality biosolids

How the Process Works

ERG’s process complements the traditional separation-based process, and can be implemented at any point after the waste stream passes through a facility’s primary and/or secondary clarifiers.

Due to variations in separation processes from facility to facility, each facility’s professionals can determine where in their process ERG’s technology will have the greatest benefit. ERG will scale its system to meet each facility’s need.

The more concentrated nutrient levels are at the point where ERG’s process is deployed, the more cost-effective the process becomes.

-

Step 1The waste treatment plant removes rags and grit, and the remaining separated solids and nutrients are funneled into the ERG system.

Step 1The waste treatment plant removes rags and grit, and the remaining separated solids and nutrients are funneled into the ERG system. -

Step 2The ERG system cuts, chops, and grinds the sludge to a very fine consistency.

Step 2The ERG system cuts, chops, and grinds the sludge to a very fine consistency. -

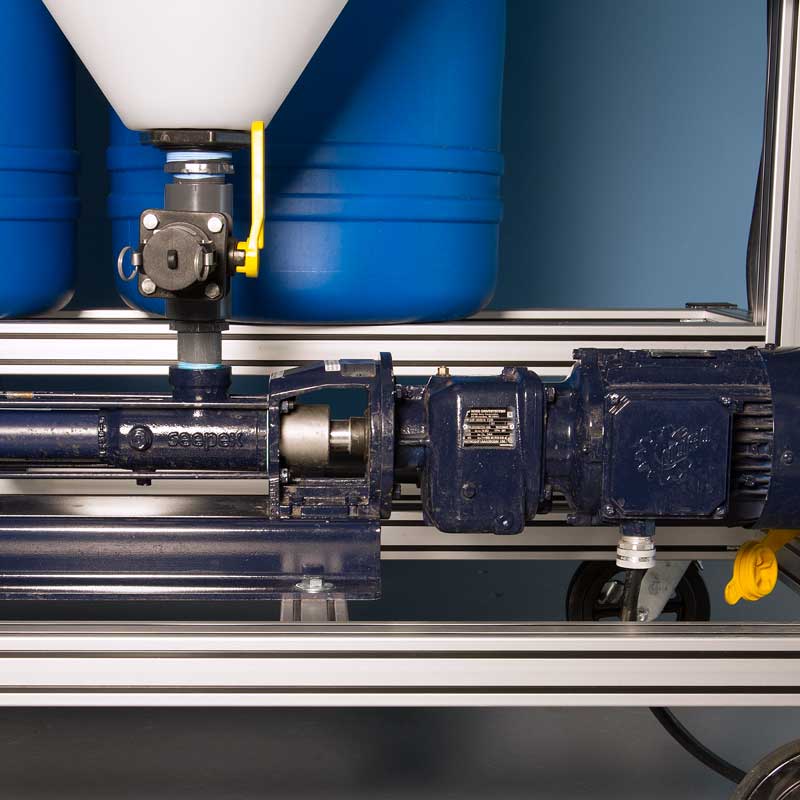

Step 3The sludge moves through a progressive cavity pump that pressures it to approximately 300 psi (pounds per square inch).

Step 3The sludge moves through a progressive cavity pump that pressures it to approximately 300 psi (pounds per square inch). -

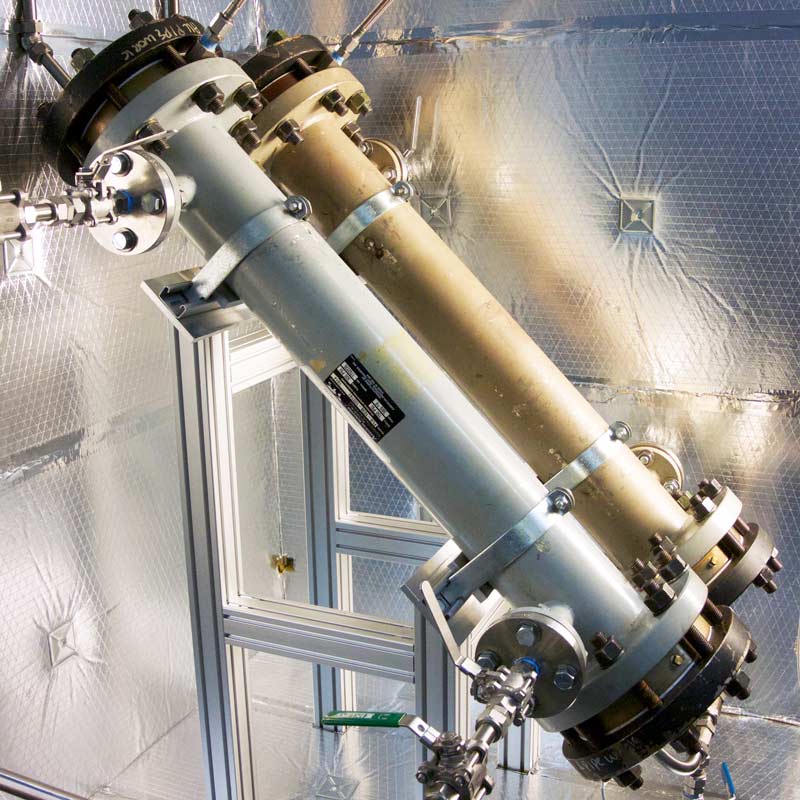

Step 4The sludge is heated to 165 degrees Celsius (329 degrees Fahrenheit), making it ready for the transformation reaction, and moves into the reactor.

Step 4The sludge is heated to 165 degrees Celsius (329 degrees Fahrenheit), making it ready for the transformation reaction, and moves into the reactor. -

Step 5In the reactor, ERG adds nitric acid, sulfuric acid, and oxygen, creating a redox reaction (oxidation reduction). In less than one minute, the redox reaction destroys all pathogens and transforms the biosolids.

Step 5In the reactor, ERG adds nitric acid, sulfuric acid, and oxygen, creating a redox reaction (oxidation reduction). In less than one minute, the redox reaction destroys all pathogens and transforms the biosolids. -

Step 6Once the redox reaction is complete, ERG cools the resulting effluent and adds aqueous ammonia to bring it to a desired pH, making it safe and useful for agricultural purposes, with greater plant nutrient value than the original biosolids. The acidity level of ERG’s trademarked ZeFluent™ can be adjusted depending on the best pH for local soils.

Step 6Once the redox reaction is complete, ERG cools the resulting effluent and adds aqueous ammonia to bring it to a desired pH, making it safe and useful for agricultural purposes, with greater plant nutrient value than the original biosolids. The acidity level of ERG’s trademarked ZeFluent™ can be adjusted depending on the best pH for local soils.

What Is the Capacity of ERG’s System?

Current capacity of ERG’s system makes it best suited for use with side streams: The ERG technology can process the thickened sludge resulting from up to 500,000 gallons of organic waste in a 24-hour period.

We anticipate scaling up production capacity to accommodate the separated solids and nutrients from one million, five million, and 15 million gallons of wastewater per 24-hour period.

What Other Waste Streams Can ERG Process?

TerraNew is currently focused on sewage, food processing, and slaughterhouse organic waste streams as they have the greatest need and immediate potential for the growth of the technology.

Over the next five years, we also plan to expand to additional problematic waste streams, such as sugar cane and animal manures.